This article will teach you how to successfully weld cast iron and some highly valuable tips to dramatically improve your cast iron welds.

Table of Contents showCast iron has 2-4% carbon, about ten times more than mild steel. High carbon content makes cast iron incredibly hard and rigid, but it also makes it brittle.

To make things worse, welding cast iron significantly increases its brittleness in certain weld zones. So, unless you follow strict welding procedures, your welds are unlikely to be successful.

There are many cast iron types, and telling them apart is challenging. It’s also easy to confuse cast iron with cast steel and cast aluminum.

The biggest issue is cast iron has a very specific alloy content depending on where it was manufactured, and matching that exact alloy content with a filler material is next to impossible.

Therefore you will have issues with weldability. It’s minimizing those issues which will give you the best chance of success.

Cast irons are also prone to embedded casting impurities and lubricants. So, cast iron welds often have porosity, making them more likely to crack.

Think of carbon in cast iron as an internal element that must remain “free” during the welding and cooling phase.

Since cast iron has excessive free carbon, it easily binds with iron to form iron carbides in the weld area. Iron carbides are extremely hard, non-ductile, and brittle.

So, if the free carbon fuses with iron, your cast iron welds will likely fail.

Carbon in cast iron creates brittle zones in the weld area if the weld is cooled rapidly. But, if the cooling process is slow, the carbon precipitates as elemental carbon.

It’s vital to prevent iron carbide formation, and there are numerous ways to achieve that, including cast iron preheating and using special alloy filler metals.

Cast iron is not a ductile material. It cannot “flex,” not even a little. Take mild steel as the opposite example — you can bend or deform it with a hammer before it cracks.

But you cannot do the same with cast iron.

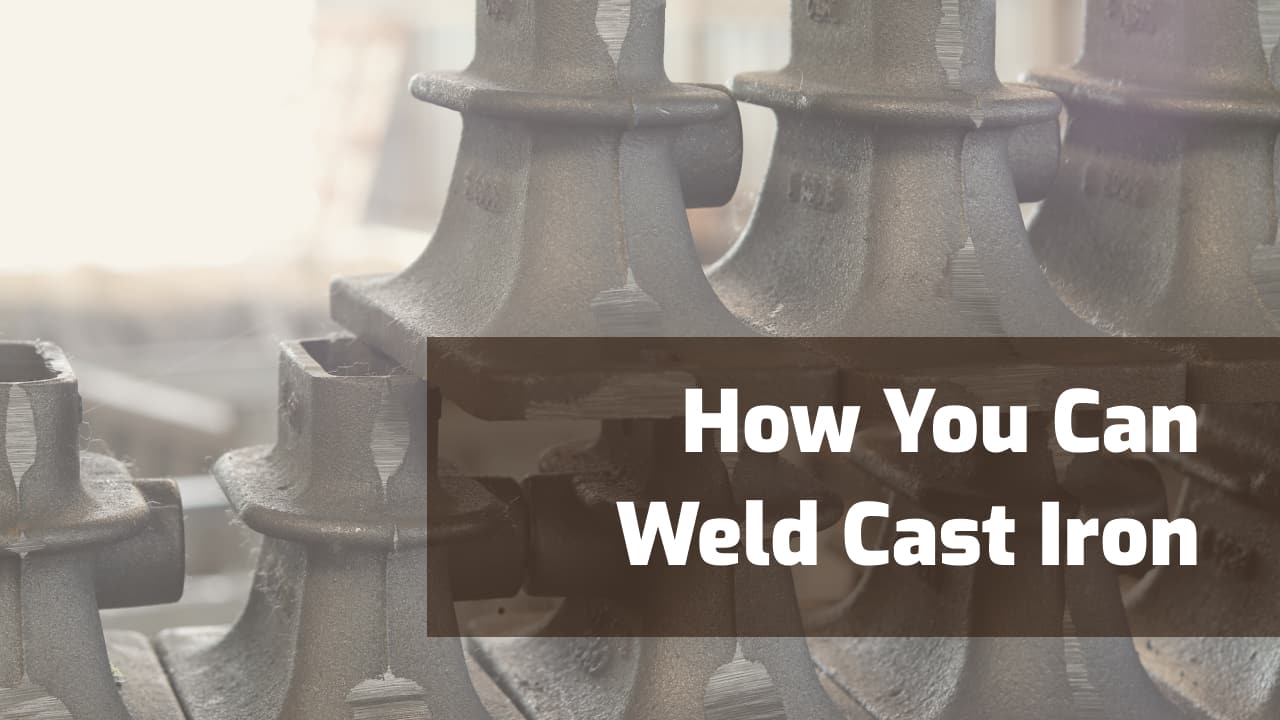

Welding cold cast iron creates immense localized heat. But, the hot weld metal cools and contracts rapidly as the heat propagates through the material and air.

However, since cast iron cannot “flex,” it easily cracks due to internal stresses caused by weld shrinkage. Ductile materials, like mild steel, yield and accommodate for weld shrinkage by re-aligning the material.

But cast iron can’t undergo the same deformation and cracks as the cooling weld pulls the surrounding metal.

Post-weld cracking is more likely to occur in the partially melted zone (“PMZ”) and heat-affected zone (“HAZ”) than in the weld metal itself. The PMZ is a zone between the weld metal and the HAZ.

These zones are at the highest risk of developing iron carbides and high-carbon martensite (extremely brittle microstructures). But, they require a different approach to prevent brittle structure formation.

In a nutshell, the weld metal cools and starts pulling the PMZ and HAZ as it contracts. But, if these two zones become hardened (and brittle), they will crack.

That’s why most failed cast iron welds crack right at the edge of the weld, not in the center. It’s not the welds that fail, but the PMZ and HAZ of the cast iron part.

How to prevent cracking in these two zones:

Cast iron is one of the hardest materials to weld. It takes experience and numerous steps to get it right.

Besides near-zero ductility and carbon’s propensity to create iron carbides, welding cast iron is difficult due to porosity.

Engine blocks, transmission cases, gearboxes, industrial pumps, and similar cast iron equipment tend to absorb oil as they are very porous. Welding ignites the deeply embedded oil, causing gasses to get trapped and create porosity in the welds.

Iron castings can also have embedded impurities from poor casting procedures, especially old ones. You can unexpectedly run into some impurities along the joint, which can cause:

Most cast iron repairs are focused on welding cracks. But cracks in the cast iron tend to propagate as you try to weld them. The welding heat and cast iron’s inability to “flex” means easy crack propagation.

Thankfully, drilling holes at the ends of the cracks is highly effective at containing the cracks from spreading.

You can weld cast iron with most standard arc and open-flame welding processes, like MMA, TIG (GTAW), MIG (GMAW), and Oxy-acetylene (OAW). But, the stick welding (SMAW) process offers the best welding characteristics for this material.

Stick welding is the industry’s “go-to” choice for cast iron. While stick welding creates welding fumes that limit weld visibility, it also produces concentrated heat, allowing you to move quickly.

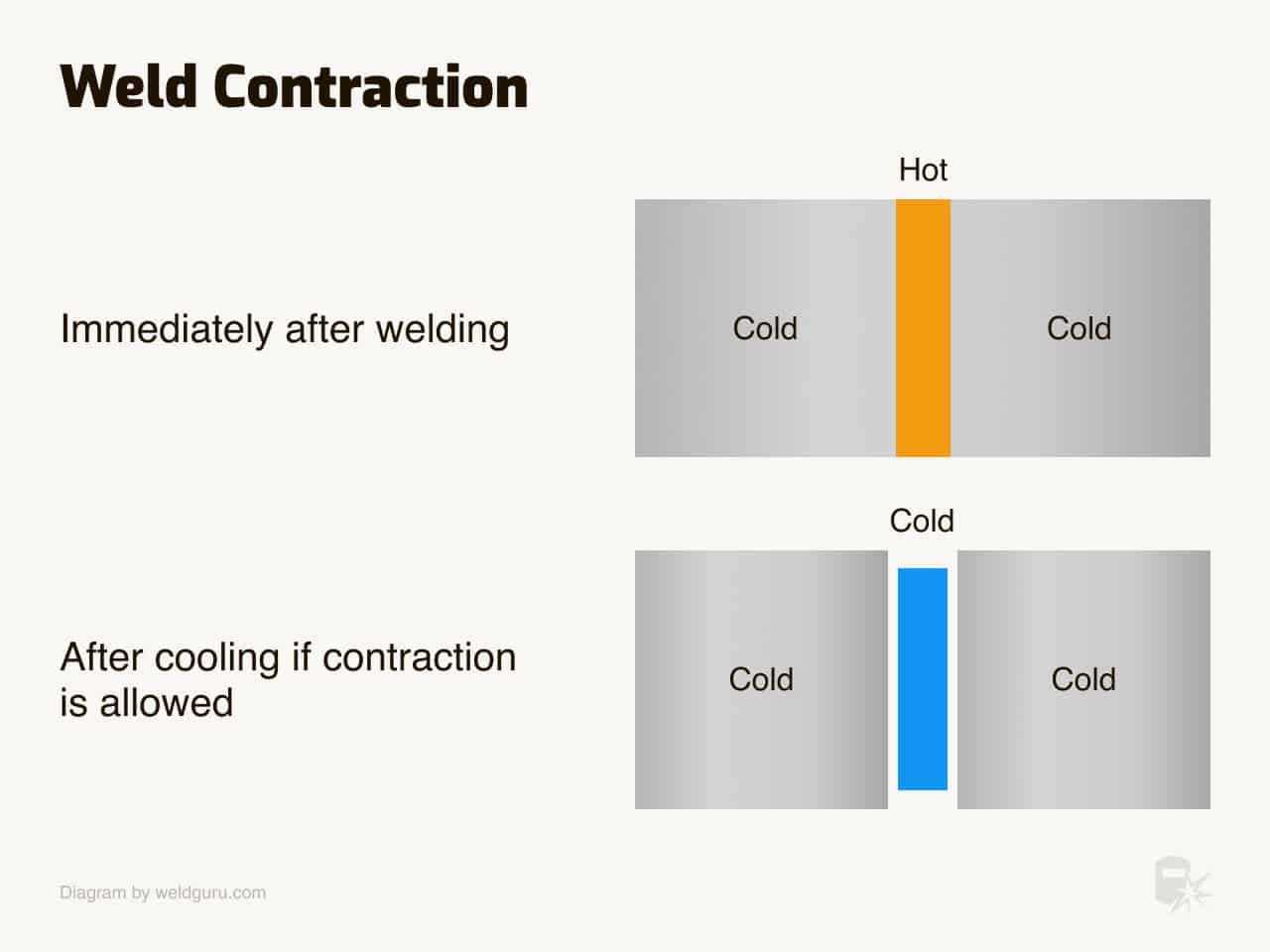

You can also switch polarity to DCEN when making surfacing cast iron welds to greatly reduce heat input and chances of HAZ and partially melted zone brittleness.

The best welding rods for cast iron are ENiCI and ENiFe-CI. Use these electrodes for cast iron to reduce the chances of weld cracking and still achieve strong joints.

It’s easy to find these stick electrodes locally and online. But, it’s more challenging to find filler alloys for other arc or oxy-welding processes.

MIG welding can be used to join broken cast iron parts. It’s best to use a nickel-alloy filler metal wire and an 80% argon / 20% carbon-dioxide shielding gas.

The most suitable wire you can get on Amazon for cast iron is ENiFe-Cl MIG wire. The ERNiFeMn-CI wire provides better results but is challenging to acquire since not many stores sell it.

It’s a typical beginner mistake to use the ERNi-1 for MIG welding. While the ERNi-1 contains pure nickel, it also has 3% titanium, which easily combines with free carbon and forms titanium carbides.

Use short-circuit arc transfer to minimize heat input and narrow the HAZ. But, it’s vital to make test welds on scrap pieces to ensure that the short-circuit MIG produces the needed penetration depth and proper fusion on the edges of the weld.

You can also use a pulsed MIG welding process to reduce heat input without significantly affecting penetration. This is highly recommended.

Depending on who you ask, TIG is the best or worst way to weld cast iron. Many welders avoid TIG for cast iron because its arc concentrates too much heat and has a slow travel speed.

However, you can use advanced pulsed TIG waveforms and a foot pedal for maximum heat control.

It’s also the only arc welding process that allows maximum weld pool visibility, precision, and the ability to manually place each droplet of filler metal.

If you are good with TIG and have a welding machine with a pulse option, you can adjust the DC TIG pulse for minimum heat input or set the AC TIG to oscillate between DCEN and DCEP with each having its amperage amplitude set at low and high values.

Add in the foot control, and you’ll have phenomenal control over the heat input, avoid HAZ and PMZ cracking, and enjoy all of the benefits of the TIG process.

You can use these filler metals for TIG welding cast iron:

Repairing cast iron with FCAW has limited applications. The only AWS-recommended flux-cored wire for cast iron is the ENiFeT3-CI, which is rare on the market.

The ENiFeT3-CI has a similar composition to the ENiFe-CI MIG and TIG wire but has a higher manganese content to resist hot cracking.

I don’t recommend flux-cored for cast iron. This highly specialized FCAW application is best suited for automated welding of thick cast iron parts, not for manual casting repairs.

You can use oxy-acetylene to repair cast irons, but it’s a highly inefficient process compared to arc welding. Today, oxy-welding is rarely used for cast irons in professional environments because it requires a lot of fuel and provides prolonged travel speeds.

I recommend oxy-fuel welding only as a last resort (i.e., you don’t own an arc welder). Oxy-fuel is not cheap, and you’ll need a lot of it.

You’ll need these filler metals:

Braze welding is a great way to join cast iron when joint strength is not paramount. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak.

Brazing doesn’t melt the base metal. Instead, it only uses the temperature needed to melt the filler metal.

The low heat is unlikely to cause brittleness in the HAZ, and since there is no PMZ, brazing is highly likely to keep the joint together. But, the mechanical properties of brazed joints are low, and the joint strength will be lower compared to stick welding, for example.

Brazing is performed using the oxy-fuel torch and copper-zinc filler metal. Be careful of overheating the joint because zinc can evaporate and create porosity.

In addition, zinc is highly toxic and should not be inhaled. Use a welding respirator and weld outside or in a well ventilated area.

Use these filler metals to braze weld cast iron. Don’t forget that brazing requires fluxing, and a borax–boric acid type flux is commonly used for the copper-zinc filler metals.

Welding cast iron comes down to pre-cleaning, preheating, applying the suitable filler alloy, and relieving the internal stresses.

But before you do that, you must identify the cast iron type you are working with.

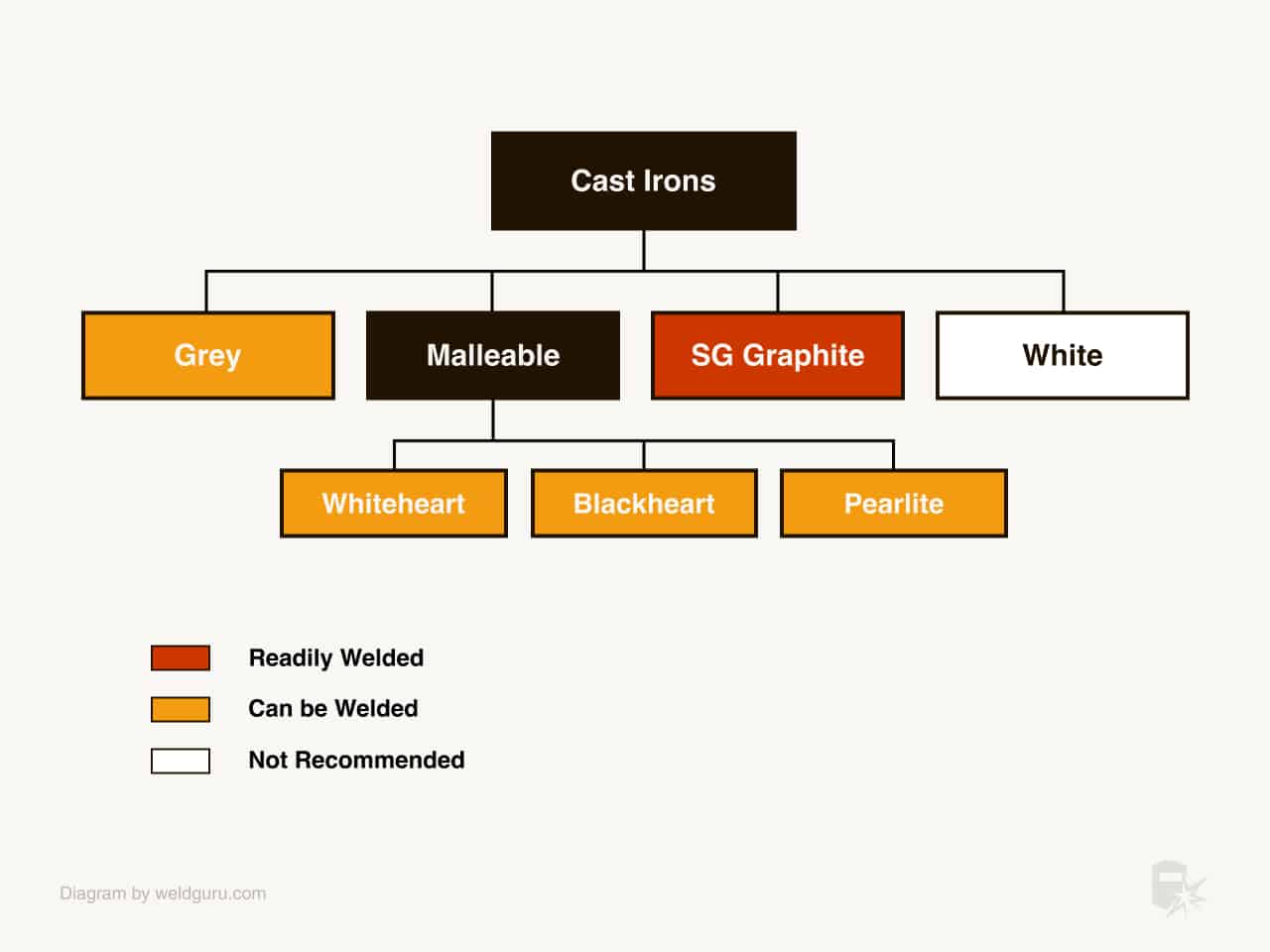

There are four main types of cast iron, and you can weld three of them. Identifying the cast iron is challenging unless you have a specification verifying the material’s chemistry.

But here are some cues that can help you:

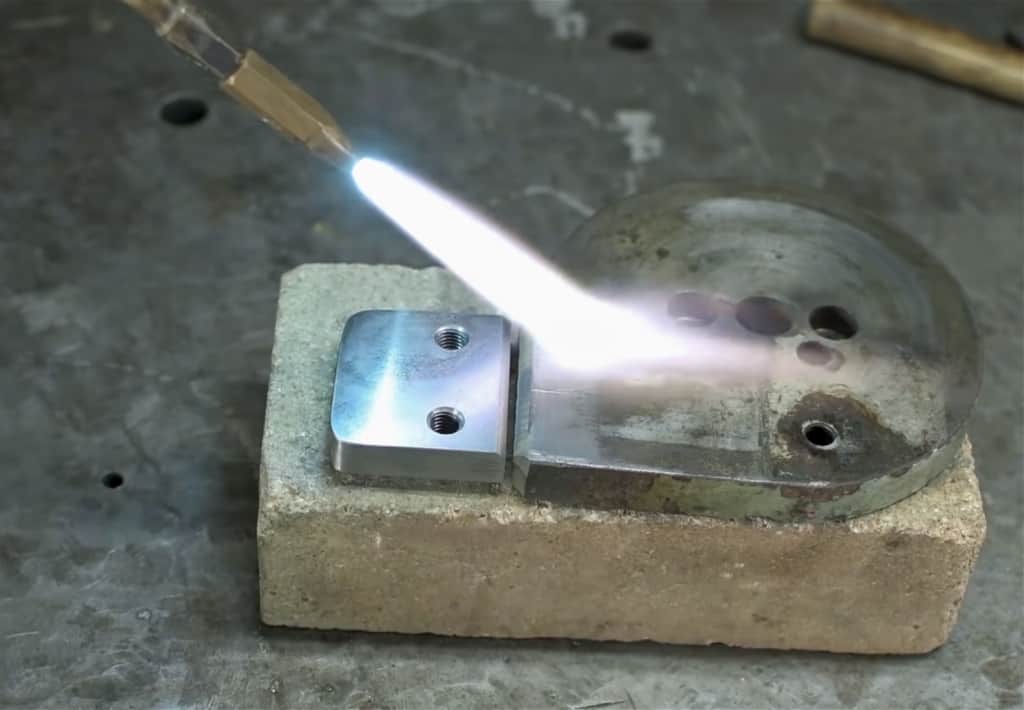

It’s crucial to preheat the whole casting uniformly and slowly. If you maximize the heat output on your oxy rosebud, you’ll heat the surface area far faster than the metal beneath it, resulting in uneven expansion, which could lead to cracking.

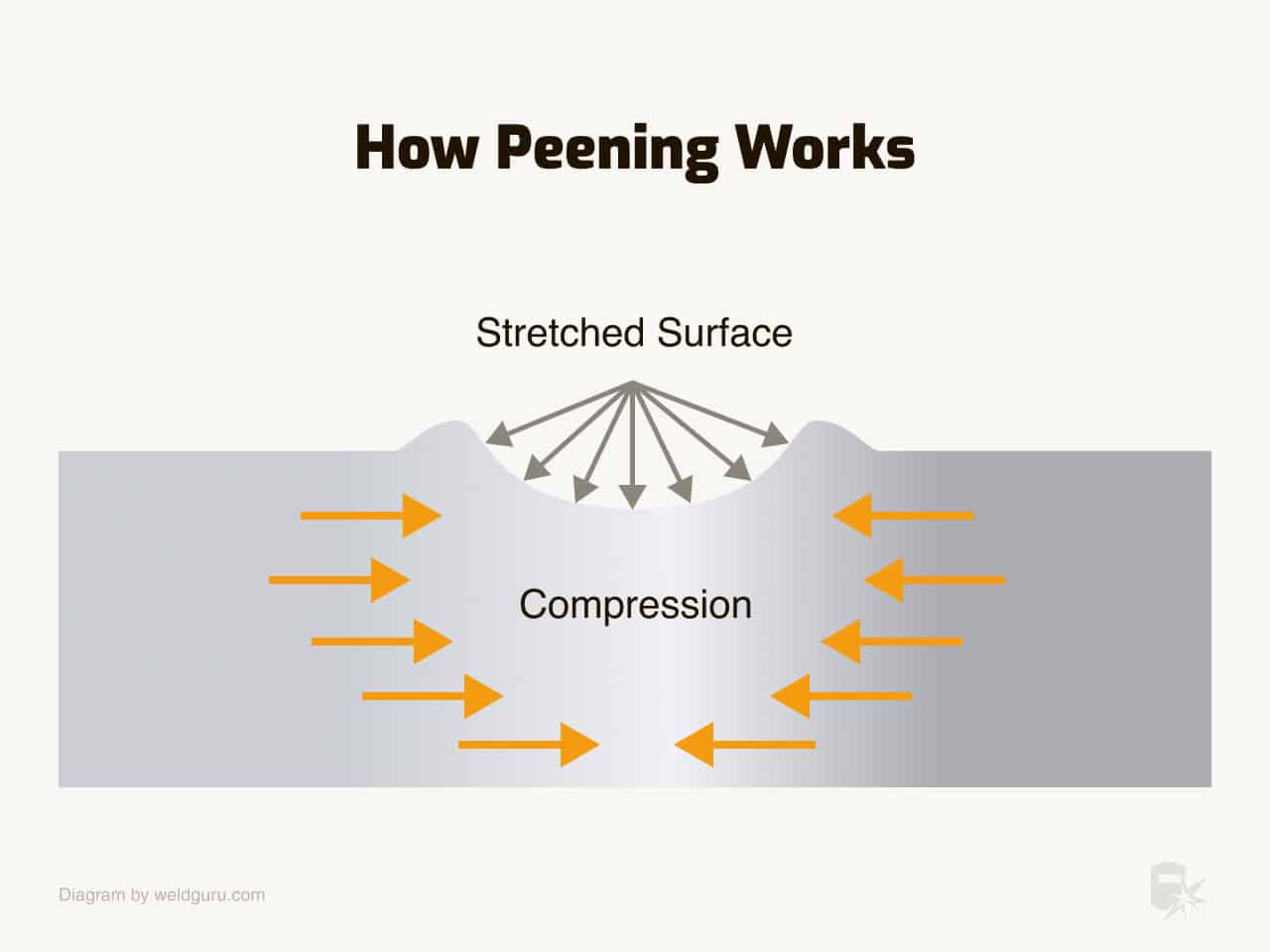

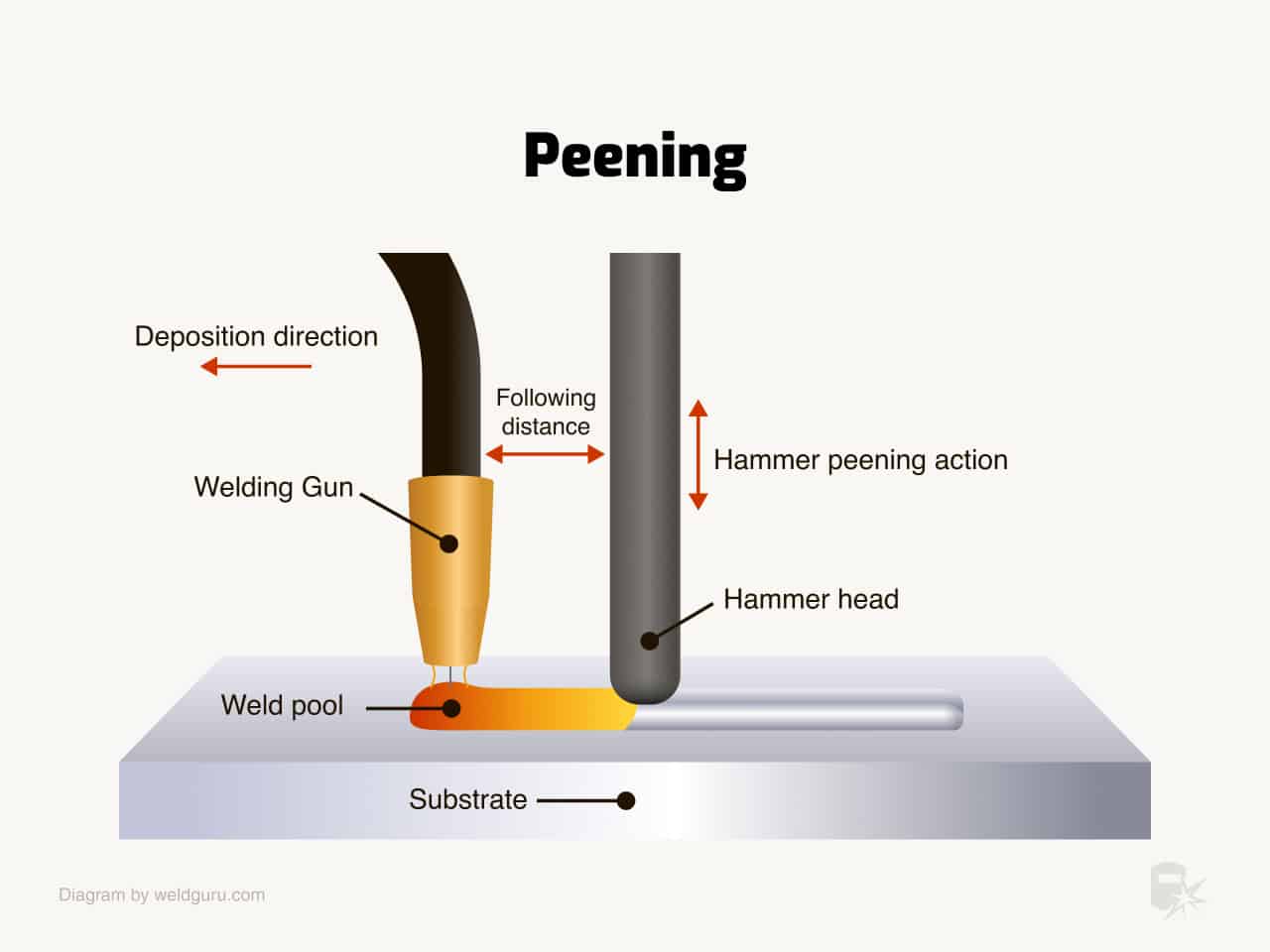

You’ll need a peening hammer because the ball point best directs the force into the surrounding metal.

Don’t let the bead cool. Hit it while it’s still red-hot multiple times perpendicularly with moderate strength to fight the contracting force.

Peening will significantly reduce the chances of PMZ cracking because the shrinkage force will be much weaker, and the area between the weld and the HAZ won’t easily crack.

To maximize the weld area ductility for improved machineability or to generally reduce the chance of cracking, some form of PWHT is needed.

There are highly specialized PWHT methods using industrial oven heaters. But you’ll have great results with basic PWHT stress relief too.

Heat the entire casting to about 600°C (1100°F) and let it cool slowly, covered with sand or a welding blanket.

Alternatively, you can just cover the casting after welding at its preheat temperature. Heating it more helps to relieve stress, but if you are welding something like a cast iron skillet or a stove, you don’t have to waste oxy-fuel for PWHT.

Welding cast iron is challenging, but you can handle it with some practice. Keep the heat as low as necessary, weld fast with intermittent welds, and use the appropriate filler metal. Add in preheating, peening, and slow post-weld cooling, and you’ll have a far higher chance of success.